Many accidents were caused by falls of stone or of coal, men falling down shafts, the use of gunpowder for blasting, and breakages of the winding ropes which were used both for raising coal to the surface and for raising and lowering the miners to and from the mine.

Accidents were numerous, so numerous in fact that scarcely any attention was given to them and they were rarely recorded. In a way this is understandable, because these were often minor accidents. Major accidents, involving the loss of lives, naturally caused greater concern. These were caused by much more terrifying factors inherent in coal mines.

Three principal evils

The Sunderland Society had this to say:

“The three principal evils with which collieries had to contend, were fire damp, choke damp and water.”

It was the opinion of the society that:

“The last of these [water] has been overcome by the invention of the steam engine and its successive improvements; but the tremendous effect of the hydrogenous and carbonic fluids continue unmitigated.”

Evidence shows that while this statement is accurate in what it says about gas, it is perhaps a little optimistic in what it says concerning water. Although the steam pump had indeed largely solved the problem of draining the mines under normal conditions, the dreadful inundation at Heaton Colliery in 1815, in which 75 men and boys died, bears witness to the fact that flooding could still be a source of danger under certain conditions.

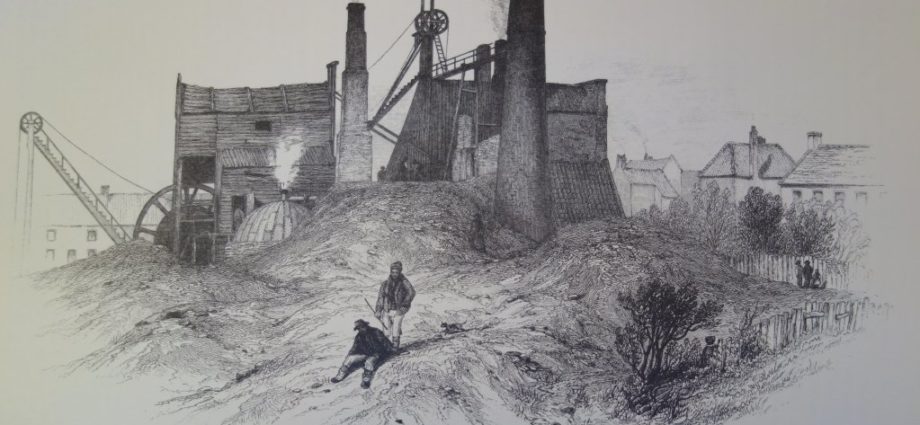

The steam pump

By about 1800 Watts’ steam pump was employed in most of the northern mines making possible the working of seams which the Newcomen pump would have been incapable of draining. One of these seams was Wallsend High Main where it was necessary to draw off 18 times the weight of water to the weight of coal mined.

Although in general, Watts’ steam pump was well able to cope with the spasmodic accumulations of water which percolated through the overlying rocks into the bottom of the mine, there occurred several fatal inundations which it was totally inadequate to deal with. These disasters included the ones at Tawnley in 1828 when a man was killed, at Beamish in 1832 when two were killed, and at Farnacres in 1840 when five were killed.

Heaton Main colliery disaster

By far the worst inundation in the history of the northern coalfield, however, took place on Wednesday 3 May 1815 at Heaton Main colliery, where 41 men, and 34 boys lost their lives. This disaster provides a perfect illustration of the type of conditions which tended to produce inundations.

The workings at this time were in the main seam which was situated at very great depth, having a considerable dip or inclination from one side to the other, the shafts being at the low side. The trouble occurred because of the existence of an old mine known as Heaton Banks, which had shafts distinct from those of Heaton Main. Over the years these old shafts had become covered over with earth and plants, and, more importantly, had entirely filled up with water. At about 4:30 on the morning of Wednesday 3 May this vast accumulation of water:

“broke through the coal in the north west part of the present colliery [Heaton Main] at a point where the strata are disturbed by a dyke, and inundated the workings… The water rushed in with dreadful rapidity and flowing naturally to the lower parts of the workings soon cut off the only means of escape, by closing the bottom of the shaft, in which the water soon rose to the depth of 19 fathoms. “

Most of the men were known to be in a high part of the mine where it was likely that the water had not reached but it proved impossible to get to them because the shafts of Heaton Main were flooded and the shafts of the old workings, Heaton Banks,

“were choked up by earth etc which covered their mouths and which when deprived of the support of the water, having fallen in, dragged after it many trees which had been planted in the area.”

Three large steam pumps were “instantly employed”, one of them being of 130 horsepower but these made no impression on the water, which steadily gained upon them, so that:

“when the lowest shaft was plumbed early on Friday morning, it was found to be 33 fathoms.”

The old mine

And so 75 people died! The fault was not in the steam pump, for even if it had been capable of raising such vast quantities of water in a very short time, it could not have prevented the deaths of those caught up in the deluge. The crux of the matter is that the inundation should never have happened in the first place. It was only made possible because of ignorance as to the extent and the nature of the old mine. On the day of the disaster, between Heaton and Benton Bridge, seven old shafts in all, caved in, leaving great chasms and apparently:

“of many of these, the surface [had] exhibited not the least vestige, nor was the existence of them known in the neighbourhood.”

In addition to this, subsequent inquiries unveiled what should have been known all along, that the old colliery had been discontinued,

“on account of the influx of water, which was so great that seven engines of the construction of that day could not get the better of it.”

If this accident pointed to any one thing it was to the need for registered plans of the workings of every colliery, as was common practice in the mines of France and Belgium. Such plans, together with careful inspection, would have revealed the danger from the old workings, which could then either have been regularly drained of water, or else properly filled in. They would almost certainly not have been left to build up the conditions which eventually produced such a tragedy.

Unfortunately, even when the need for plans of workings was so drastically highlighted, there was no voluntary provision of them. It took a long, hard, struggle ending in legislation which forced owners to have plans of all workings drawn up.

Gas

The other major cause of accidents in collieries was gas. Most coal mines contain harmful gases and of these firedamp (or methane) is undoubtedly the greatest evil. Being lighter than air, firedamp accumulates under the roof. Although it can safely be breathed, a mere spark can set the inflammable gas alight with the suddenness of an explosion. It is present in the coal itself, between the layers of strata which usually lie parallel to the surface, and is discharged into the workings in two ways; firstly when the coal is broken and removed by the hewers and secondly it is permanently ejected from chinks in the roof on fissures in the strata. These latter were commonly called ‘blowers’ or ‘fizzers’ and often gave off enormous quantities of gas. Sir James Lauder, for instance, found a uniform current produced in one of his mines for two years and nine months. In spite of this, these blowers in themselves excited no fear in the miners for

“In some instances, the gas from the blowers has been collected in bottles by the pitmen, closed with clay and afterwards lighted in their houses by making a small hole in the clay.”

Firedamp was a major problem in the Newcastle coal mines for

“This evil (firedamp), though belonging to all coal mines has been most seriously experienced… in the important mines in the neighbourhood of Whitehaven and Newcastle in this country.”

By far the worst seam in the Newcastle area was the Bensham seam, which in the early 19th century was being worked at Wallsend and at Jarrow. Hair refers to it as “a subterranean gasometer” and describes how at Wallsend

“The vast evolution of firedamp from one particularly bad part of the seam is carried by means of a pipe to the top of the mine where it burns with the utmost fury and… sounds like the roaring of a blast furnace.”

Writing in 1849 about the quantity of firedamp produced at Wallsend, George Dodd says that it was so great

“that an attempt was made a few years ago to employ the gas from this colliery for gas lighting in the neighbourhood.”

Carbon Dioxide

Another gas which was present in most coal mines was carbon dioxide or ‘choke damp’ which forms around coal that has been in contact with the outer atmosphere, either directly or through a light covering of soil for some time. Choke damp is not inflammable but as its name suggests, if inhaled in large enough quantities it produces suffocation. Generally, it was regarded as less dangerous than firedamp, because its fumes would extinguish the miner’s candle, thus warning him of its presence before it could harm him. He would then disperse it by wafting his jacket or a piece of sacking.

Another type of gas which was not normally present in the mines but which did in fact claim large numbers of lives was carbon monoxide (or after damp). It was formed by the burning of the methane and quickly filled up the whole mine, suffocating, those miners who survived the explosion.

It was commonplace in explosions for more men to die as a result of suffocation than as a result of the actual explosion.

However, it was primarily the presence of the inflammable firedamp that posed the two major technical problems which affected safety in the mines during the first half of the 19th century.

These were the problems of lighting and ventilating the mines.

Read more in Part 3, coming soon

Please follow us on social media, subscribe to our newsletter, and/or support us with a regular donation